Diesel Engine also known as a compression-ignition engine . It is an internal combustion engine that uses the heat of compression to initiateignition to burn the fuel, which is injected into the combustion chamber. This is in contrast to spark-ignition engines such as a petrol engine (gasoline engine) or gas engine (using a gaseous fuel as opposed to gasoline), which uses a spark plug to ignite an air-fuel mixture. The engine was developed by German inventor Rudolf Diesel in 1893.

The diesel engine has the highest thermal efficiency of any regular internal or external combustion engine due to its very high compression ratio. Low-speed diesel engines (as used in ships and other applications where overall engine weight is relatively unimportant) can have a thermal efficiency that exceeds 50%.

Diesel engines are manufactured in two stroke and four stroke versions. They were originally used as a more efficient replacement for stationary steam engines.

Two-Stroke Diesel Engine : The working of two-stroke diesel engine is also similar to that of a two-stroke petrol engine. The advantage of the two-stroke compression engine when compared to the four-stroke compression engine are as follows

- Smoother torque

- Simpler construction and Operation

- Low initial cost

- Smaller unit

- Mostly suitable for low speed industrial @ marine application.

In the case of two-stroke petrol engine the fuel is lot due to the short circuiting loss when both ports are open but this is not case with the two-stroke diesel engine as the cylinder only contains air. hence it can be stated that the two-stroke cycle is mostly suitable for CI operations

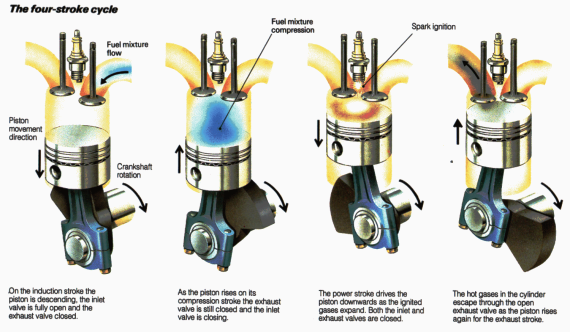

Four-Stroke Diesel Engine : The Working of this engine is similar to that of petrol engine expect the following

Suction/Induction Stroke : During this stroke only air is taken into the cylinder through the inlet valves as the position moves from TDC to BDC.

Compression Stroke : During this stroke the piston is made to move from BDC toTDC and compresses the air,which was previously drawn into the cylinder.At the end of this stroke,diesel is injected (sprayed at high pressure 100bar and above) into the cylinder and the process of combustion starts. There fore this engine is called as Compression ignition engine..

Expansion Stroke : The Operation is almost the same as in the petrol engine.

Exhaust Stroke : The Operation is also the same as in the case of petrol engine.